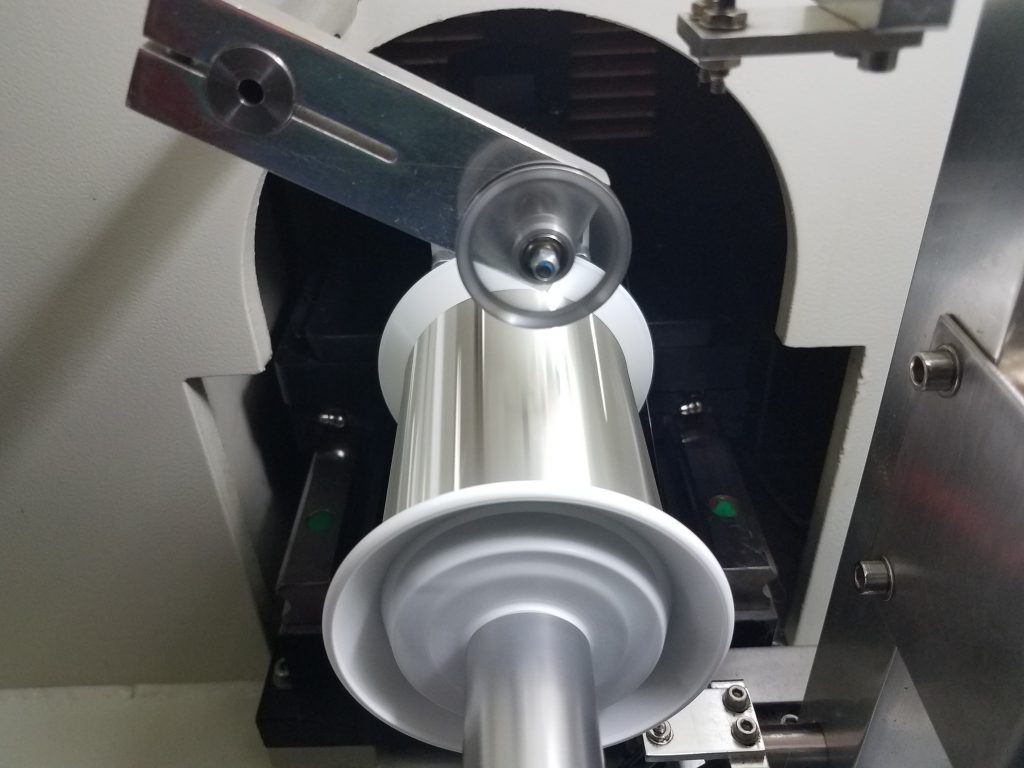

Our new modern electroplating equipment deploys in-line XRF (X-Ray Fluorescent) units on a continuous mode to add an additional layer of process control to ensure consistent plating thickness. Our proprietary chemistry allows the highest quality deposits using 99.999% pure silver anodes. Afterwards, all the products are produced from Niehoff multiwire machines and Niehoff bunchers with latest electronic tension control and laser guided automatic traverse systems. Our Hacoba/Niehoff bobbin winding machines use elegant solutions to apply the lubrication of our customers choice consistently. The single end products are produced on the latest equipment from SAMP and Niehoff with proprietary in-house upgrades to ensure absolutely perfect surface quality along with using in-line laser measurements to guarantee the most consistent diameter.