Decades ago when the founders of Accel were young lads, there was PD135 (aka T-Flex and Alloy135) followed by CS-95 and CT-37 (aka copper tin alloy) followed by Fisk’s Percon 17, 24 and 28. Each step of the way for the past 50 years, they all told you it is the next best thing. With each iteration, it is sort of the newest and best toothpaste with this or that additive. Accel now is proud to offer you the latest same thing that they have…the goal of our XL70 alloy is to provide you the physical properties to meet MIL specs and Boeing Specs and so on…Additionally, our XL70’s composition and properties are equivalent or better to Percon 24 and PD Alloy 135 (tensile strength greater than 60 KSI for XL70).

Understanding the requirements of high-performance stranded alloys, Accel has successfully developed a flawless manufacturing process that exceeds the most stringent industry standards and regulatory entities such as Navair, MIL-Specs and BMS Specifications.

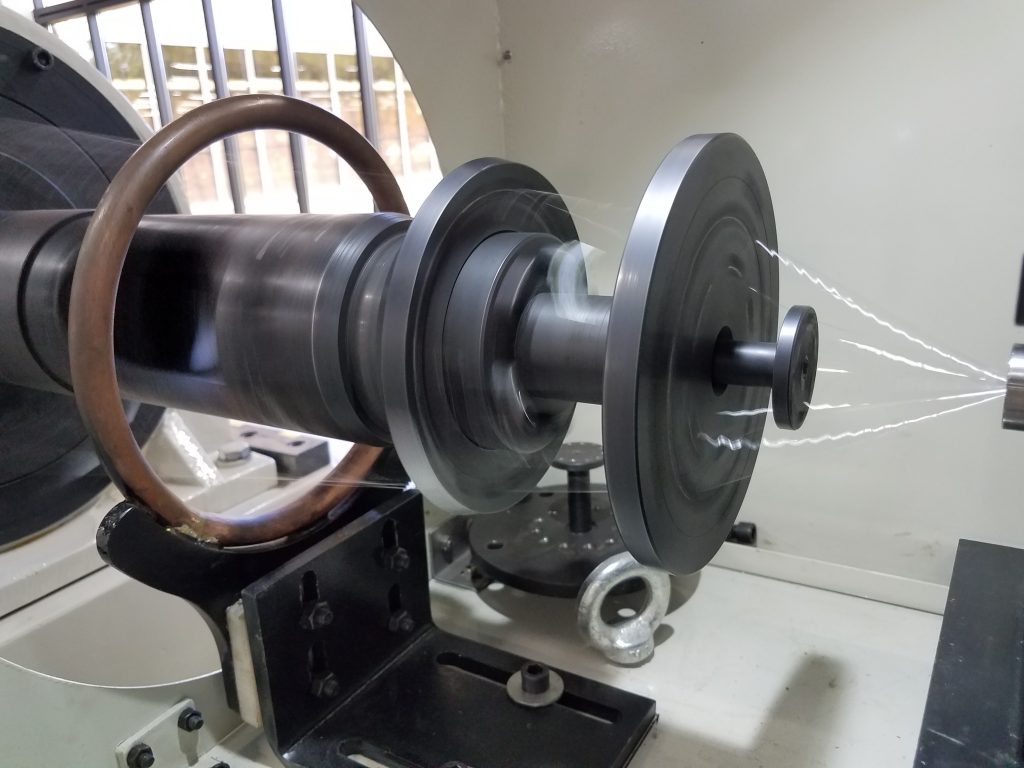

With our XL70, we electroplate it using our state-of-the-art platers enhanced with in-line XRF units and wire drawing machines with laser guided traverse units. The key then is our tubular stranders which are all brand new with awesome tension controls making the smoothest product for our customers to use hassle-free!

Email or call us for a quote today!